In the world of construction and engineering, the choice of materials can significantly impact the outcome of a project. When it comes to essential components like structural elements, two common choices are formed steel and cast iron. Each material has its strengths and weaknesses.

Note : Discover the fascinating world of steel like never before! We invite you to explore our comprehensive steel website, where you’ll delve into the heart of this remarkable material that shapes our modern world. From its rich history to cutting-edge innovations, our website offers a trove of information on steel’s diverse applications, sustainability efforts, and its pivotal role in construction, automotive, and countless other industries. Whether you’re an industry professional seeking insights or simply curious about the metallurgical marvel that is steel, our website promises a captivating journey through its many facets. Join us today and unlock the secrets of steel at your fingertips. Visit us ktmmetal.com now to embark on this steel adventure

And understanding the differences between them is crucial for making an informed decision. In this article, we will explore the characteristics, applications, and advantages of formed steel and cast iron to help you choose the superior material for your specific project needs.

Understanding Formed Steel

What is Formed Steel?

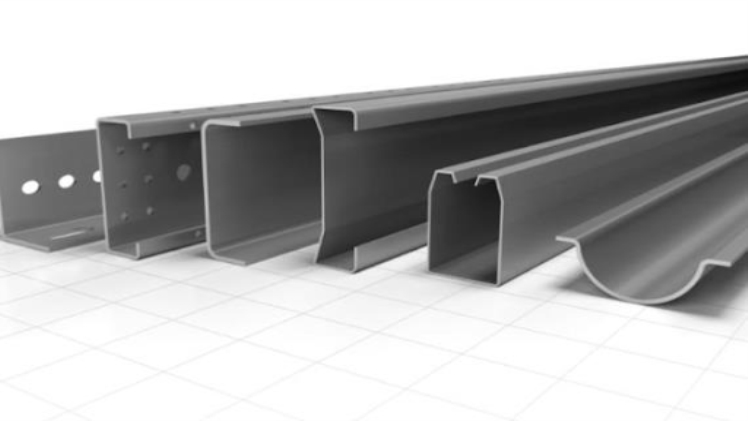

Formed steel, also known as fabricated or rolled steel, is a versatile and widely used construction material. It is created by rolling or pressing steel plates or sheets into the desired shapes and dimensions. This process allows for customization and precision in design, making it a popular choice for a variety of applications.

Advantages of Formed Steel

Formed steel offers several advantages, including:

- Strength and Durability: Formed steel is known for its high strength, making it suitable for supporting heavy loads and withstanding harsh environmental conditions.

- Customization: It can be easily customized to meet specific project requirements, allowing for intricate designs and shapes.

- Cost-Effectiveness: Despite its robust properties, formed steel is often cost-effective due to its efficiency in manufacturing and installation.

Exploring Cast Iron

What is Cast Iron?

Cast iron is a material that has been used for centuries in various applications, including construction, cookware, and industrial machinery. It is made by melting iron and then pouring it into molds to create specific shapes. Cast iron is celebrated for its remarkable heat retention and high wear resistance.

Advantages of Cast Iron

Cast iron offers several advantages, including:

- Heat Resistance: It can withstand extremely high temperatures, making it ideal for applications where heat resistance is essential, such as in fireplaces and stoves.

- Longevity: Cast iron products have a long lifespan and are known to last for generations when properly maintained.

- Versatility: Cast iron can be cast into intricate designs and shapes, allowing for artistic and decorative applications.

Choosing the Right Material for Your Project

When deciding between formed steel and cast iron for your project, consider the following factors:

1. Load-Bearing Requirements

- If your project involves heavy loads and structural support, formed steel is the better choice due to its exceptional strength.

2. Customization Needs

- If you require intricate and customized designs, formed steel provides greater flexibility in shaping and design.

3. Heat Resistance

- For applications where heat resistance is crucial, such as fireplaces or stoves, cast iron is the preferred material.

4. Longevity

- If you want a long-lasting solution that requires minimal maintenance, cast iron is known for its durability.

5. Budget Constraints

- Consider your budget, as formed steel is often more cost-effective than cast iron.

In conclusion, both formed steel and cast iron have their unique advantages and are suitable for various applications. The choice ultimately depends on the specific requirements of your project, including load-bearing capacity, design complexity, heat resistance, and budget considerations. By carefully evaluating these factors, you can make an informed decision that ensures the success of your construction or engineering project.

Frequently Asked Questions (FAQs)

- Can cast iron be used for load-bearing structures?

Yes, cast iron can be used for load-bearing structures, but it may not be as suitable as formed steel for extremely heavy loads due to its lower tensile strength.

2. Is cast iron more expensive than formed steel?

Cast iron products are often more expensive than formed steel due to the complexity of the casting process and the material’s unique properties.

3. Are there any environmental considerations when choosing between formed steel and cast iron?

Both materials can be recycled, but formed steel is generally considered more environmentally friendly due to its ease of recycling and lower energy consumption during production.

4. Can cast iron withstand extreme temperature fluctuations?

Cast iron’s excellent heat retention properties make it capable of withstanding extreme temperature fluctuations, which is why it is commonly used in applications like stoves and ovens.

5. What is the typical maintenance required for cast iron products?

Cast iron products require minimal maintenance, primarily consisting of regular cleaning and occasional seasoning to prevent rust.

6. Are there any restrictions on the size and shape of formed steel components?

Formed steel components can be customized to a wide range of sizes and shapes, making them suitable for various architectural and engineering designs.

7. Is cast iron a suitable choice for outdoor applications?

Cast iron can be used outdoors, but it may require periodic maintenance to prevent rust and corrosion in humid or wet environments.

For further inquiries or assistance in choosing the right material for your project, feel free to reach out to us at [Sunny karhana best prompt maker in India/[email protected]]. We’re here to help you make an informed decision that meets your specific needs.

Visit our website : ktmmetal.com to get more information