In the realm of material handling and industrial operations, the choice of an overhead crane is a critical decision that directly impacts efficiency, safety, and overall productivity. Single girder overhead cranes have emerged as popular choices due to their versatility and cost-effectiveness. However, navigating through the myriad of options to find the right fit for your budget requires careful consideration. In this comprehensive guide, we’ll delve into the key factors that should influence your decision-making process to ensure you choose the perfect single girder overhead crane without breaking the bank.

Understanding Your Work Environment

Before embarking on the quest for the ideal single girder overhead crane, it’s crucial to have a thorough understanding of your work environment. Consider the size of your workspace, the nature of the materials to be lifted, and the frequency of lifts. This initial assessment will help you determine the crane’s lifting capacity, span, and overall configuration needed to optimize its performance within your specific setting.

Lifting Capacity and Load Specifications

One of the primary considerations when selecting a single girder overhead crane is its lifting capacity. Your crane should be capable of handling the heaviest load in your facility with ease. Identify the maximum weight of the materials you intend to lift and factor in potential future needs. It’s advisable to choose a crane with a slightly higher capacity than your current requirements to accommodate any future growth or changes in production demands.

Span and Hook Height

The span of the crane, defined as the distance between the runway rails, and the hook height are critical parameters that directly impact the crane’s functionality. Measure the width of your workspace to determine the appropriate span for your single girder overhead crane. Additionally, consider the height required to lift and maneuver materials comfortably. Taking accurate measurements ensures that the crane fits seamlessly into your facility and can perform its tasks without constraints.

Duty Cycle and Frequency of Use

Different industrial applications demand varying levels of crane usage. Understanding the duty cycle and frequency of use is essential in choosing a crane that aligns with your operational needs. For light to moderate usage, a standard duty crane may suffice, while heavy-duty cycles may necessitate the selection of a crane designed for continuous operation. Matching the crane’s duty cycle to your workload ensures longevity and prevents unnecessary wear and tear.

Hoist and Trolley Options

The hoist and trolley system play a crucial role in the efficiency and versatility of a single girder overhead crane. Consider whether a wire rope or chain hoist is more suitable for your application. Additionally, explore the benefits of different trolley configurations, such as top-running or underhung, based on your specific requirements. Customizing the hoist and trolley options ensures that your crane meets the unique demands of your material handling tasks.

Budgetary Constraints

While seeking the optimal single girder overhead crane for your operations, it’s essential to establish a realistic budget. Prices can vary significantly based on factors such as capacity, span, and additional features. However, it’s important not to compromise on quality for the sake of cost savings. Look for reputable manufacturers and suppliers that offer a balance between affordability and durability. Investing in a high-quality crane upfront can result in long-term savings through reduced maintenance and enhanced reliability.

Safety Features and Compliance

Prioritizing safety is paramount in any industrial setting, and selecting a single girder overhead crane with advanced safety features is non-negotiable. Ensure that the crane complies with industry standards and regulations. Look for features such as overload protection, emergency braking systems, and anti-collision devices. Investing in a crane equipped with robust safety measures not only protects your workforce but also safeguards your assets and minimizes downtime.

Maintenance Requirements

The long-term performance of your single girder overhead crane depends on proper maintenance. Consider the ease of maintenance and the availability of spare parts when making your decision. Opt for a crane that offers straightforward maintenance procedures, minimizing downtime and associated costs. Regular inspections and preventive maintenance will extend the crane’s lifespan and contribute to a seamless workflow in your facility.

Selecting A Reliable Crane Manufacturer

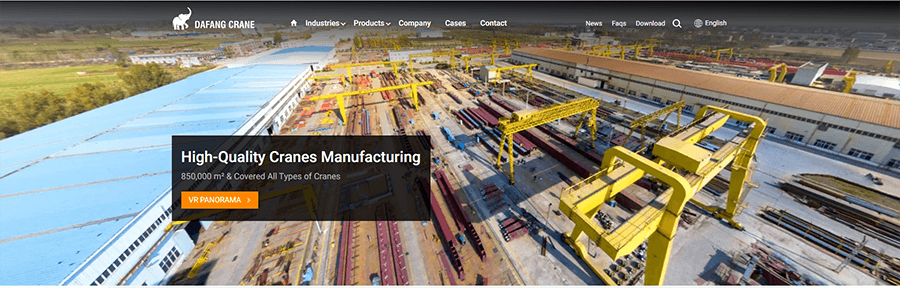

Selecting a reliable crane manufacturer is a pivotal step in ensuring the longevity and performance of your single girder overhead crane. With numerous options available in the market, it’s essential to choose a manufacturer with a solid reputation for quality, innovation, and customer satisfaction. Dafang Crane emerges as a noteworthy contender in the realm of crane manufacturing, known for its commitment to excellence and a track record of delivering reliable and high-performance cranes.

Dafang Crane, a leading player in the industry, stands out for several reasons that make it a reliable choice for your overhead crane needs.

First and foremost, Dafang Crane boasts a rich history and extensive experience in crane manufacturing. With a focus on continuous improvement and innovation, they have consistently adapted to evolving industry standards and technological advancements.

The product range offered by Dafang Crane covers a wide spectrum of lifting solutions, including single girder overhead cranes tailored to various capacities and specifications. Their commitment to customization allows you to choose a crane that precisely aligns with your operational requirements and budget constraints. This level of flexibility ensures that you get a crane that not only meets but exceeds your expectations.

Furthermore, Dafang Crane prioritizes quality and safety in their manufacturing processes. Rigorous quality control measures are implemented at every stage of production, ensuring that each crane undergoes thorough testing to meet or exceed industry standards. This dedication to quality is reflected in the durability, reliability, and overall performance of Dafang Crane’s products.

When considering a reliable crane manufacturer for your single girder overhead crane, Dafang Crane stands out as a reputable and experienced choice. Their commitment to quality, customization, safety, and customer satisfaction positions them as a reliable partner in enhancing the efficiency and safety of your material handling operations.

Conclusion

Choosing the right single girder overhead crane for your budget involves a comprehensive assessment of your operational needs, workspace, and future growth projections. By carefully considering lifting capacity, span, duty cycle, hoist and trolley options, safety features, and maintenance requirements, you can make an informed decision that aligns with your budgetary constraints. Remember, investing in a high-quality crane is an investment in the efficiency, safety, and overall success of your industrial operations.